Why inventory is bad to your company?

Inventory includes all the stock that is present inside the company. i.e. Raw Materials(RM), Work-in-Progress (WIP) and Finished Goods(FG) that are considered to be the portion of a business’s assets.

According to Lean Philosophy, Inventory is considered to be one of the 7 wastes in any factory.

How can something, which is an asset of any business, be considered as a waste? Because, there is no physical or chemical change that happens to the product when it is in inventory.

Imagine a batch production where parts are moved in batches of 100. The first component waits for the next 99 components to be processed so that it can move to the next operation. There is no value addition during waiting and this is why Inventory is considered to be the mother of all wastes.

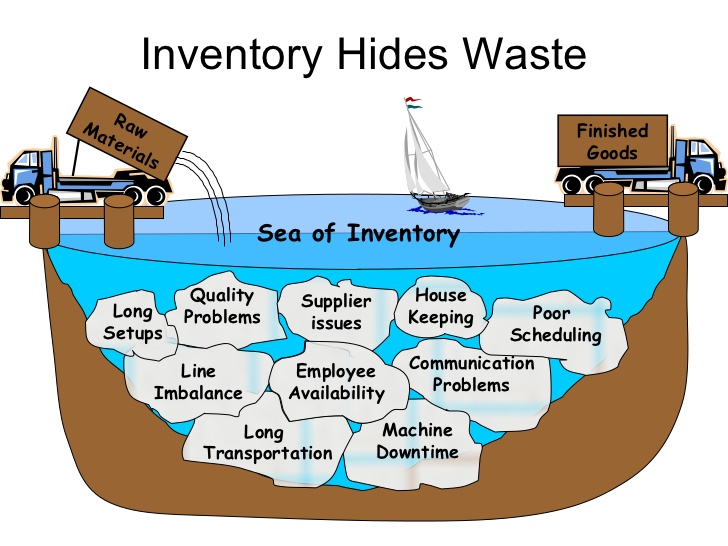

Inventory hides all the existing problems in the company. For e.g. frequent break-downs of machines, Longer Set-up times, poor Quality levels, etc. are hidden inside the factory due to inventory.

Lean focuses on reducing Inventory, thereby bringing out all the challenges faced by the company so that these challenges can be addressed.

Inventory accumulates for many reasons, some of which are listed below,

Why Inventory is harmful to the company?

But how do we do that? Where to start?We would explain in our next post.Thank you for reading this article. What are your thoughts on this? Please post them in the comments section.

Contact us for a consultation on how Hash LLP can help your business with Lean Manufacturing.

+91 9176613965

Join 3500+ Professionals who receive our Weekly Newsletter containing Simple and Practical ideas to help achieve Results in their companies.

Hash Management Services LLP, 2023 © All Rights Reserved