The Eight Pillars of TPM

The Eight Pillars of TPM Total Productive Maintenance (TPM) is a set of strategic initiatives focusing on maintaining and improving production and quality systems through the machines, equipment, processes and employees that add value to an organization. TPM has eight pillars that are mainly aimed at proactively improving the reliability of machines. People are at […]

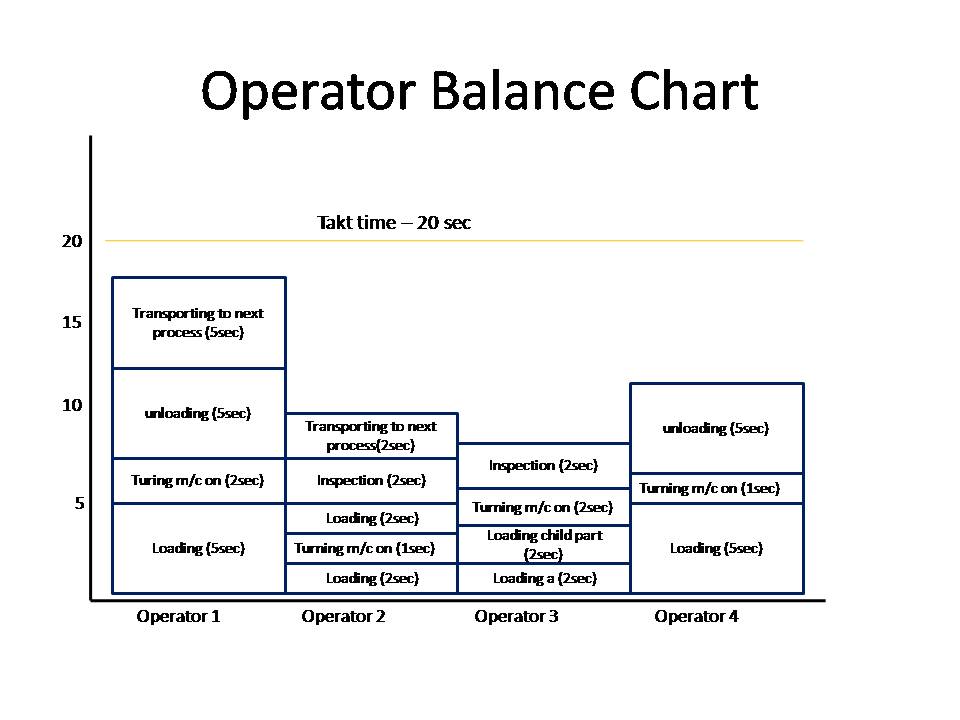

5 important steps to calculate number of operators required for a cell

5 important steps to calculate number of operators required for a cell As a manager, we are inclined to ideas like the cell or line. Consider if a cell is going to be introduced to the existing product line. You will surely estimate, how many operators will be needed for the cell. Below are the […]

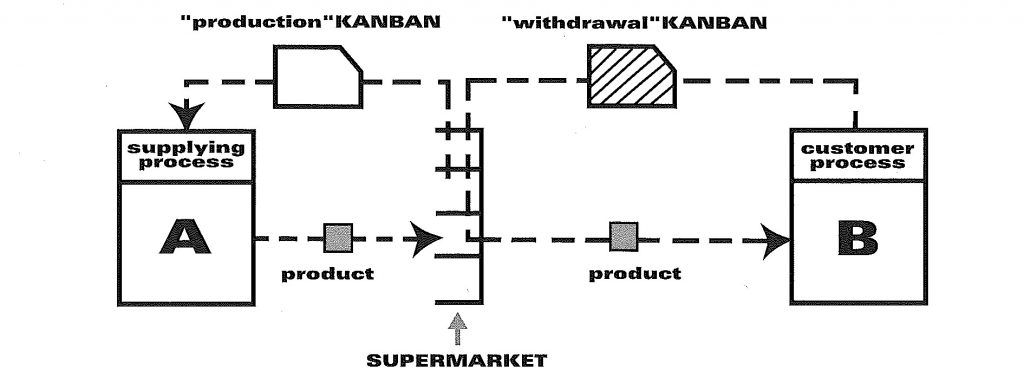

8 Key questions for drawing a future state value stream

8 Key questions for drawing a future state value stream The objective of VSM is to highlight sources of waste and eliminate them by implementing a future state value stream. Based on your answers, mark your future state ideas and then you can draw a future-state map with the same set of symbols used for current state […]

Six steps to avoid overproduction in your shop floor

Six steps to avoid overproduction in your shop floor If you are a person who is wondering why you need to avoid overproduction in the first place, then there is an another piece of article you need to read before going through this one – 5 reasons why overproduction is harmful. In lean manufacturing we try to get […]