7 Wastes in Lean Manufacturing Tamil Video

Lean Manufacturing: 7 Wastes – Tamil Video We have a previous post on the 7 wastes of lean manufacturing. We have now created a video on the seven wastes as part of our “Lean Manufacturing Lessons for people who hate reading” series. Watch it and share it with your friends. https://www.youtube.com/watch?v=bCGUAtOXw9M According to Lean manufacturing, there are […]

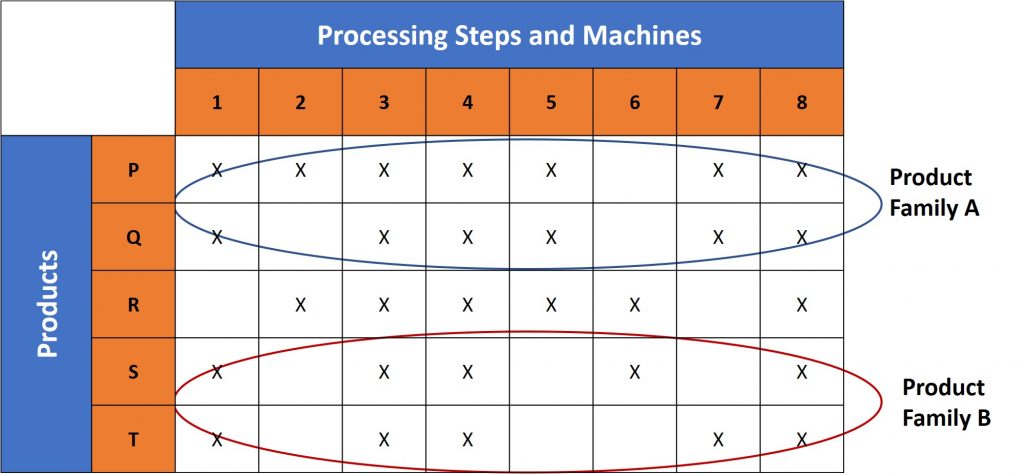

Value Stream Mapping – Selecting a Product Family

How to select a product family for value Stream mapping? This post focus on how to select a product family for value stream mapping analysis. The first step in value stream mapping is to select the right family of products. A family is a group of products that has similar processing steps and common machines […]

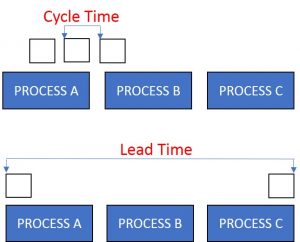

Difference between Cycle Time, Value Adding Time and Lead Time

What are the differences between Cycle Time, Value Added Time and Lead Time? Beginners in lean manufacturing often get confused with the terms Cycle Time, Value Added Time, and Lead Time. In this article, we explain these terms for easy understanding. Cycle Time The time between two successive outputs from a machine or an operation. […]

Work and Waste in Lean Manufacturing

Work and Waste in Lean Manufacturing https://www.youtube.com/watch?v=txNgJBc1Pmg Video 3: In this video I speak about the difference between “Work” and “Waste” in the lean manufacturing philosophy. Work: Any activity that brings a physical or chemical change in the product is called work. e.g. In a turning operation, work happens when the tool touches the component […]