Five Golden Rules in Gemba

Five Golden Rules in Gemba his is our First article based on the Book “Gemba Kaizen by Masaaki Imai” Gemba means the actual place where the work is done. For a manufacturing firm the Gemba is the shop floor, for a hospital the Gemba is the Treatment wards, reception and Operation theatre and for a Cinema theatre […]

Difference between Batch Processing and Single Piece Flow

Batch processing Vs. Single Piece Flow In this article, we are explaining the difference between traditional batch processing and Single piece flow. This understanding is critical for the successful implementation of Single piece flow which is the foundation of Lean Philosophy. Traditional Batch processing In traditional batch processing, every operation of the products are done […]

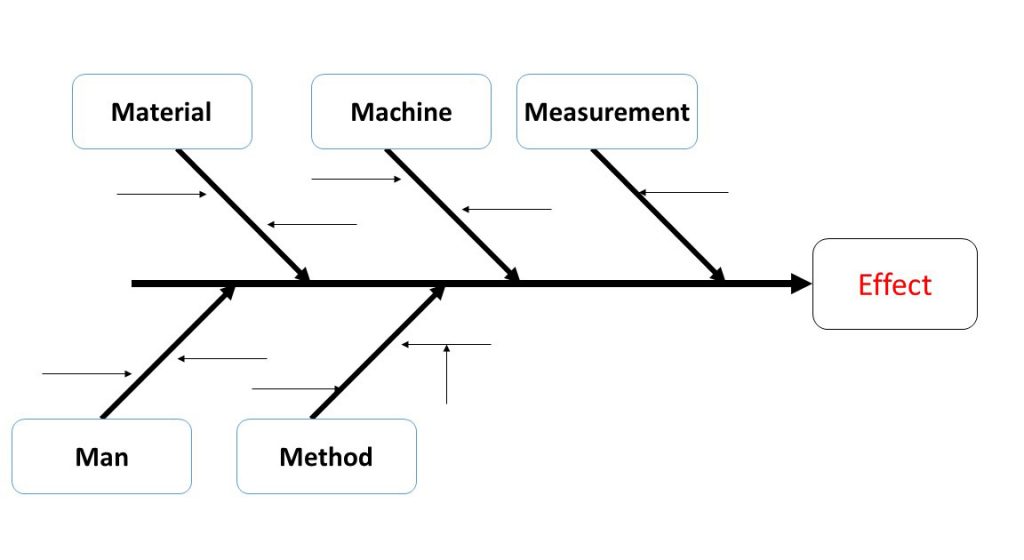

How to use Cause and Effect Diagram and Pareto analysis

Cause and Effect Diagram and Pareto Analysis Cause and Effect diagram and Pareto analysis are two of the seven basic QC tools. When both these tools are used together, they provide a complete picture of a problem. Cause and Effect Diagram Cause and Effect Diagram is a technique for identifying the possible causes of an observed problem […]