8 Key questions for drawing a future state value stream

The objective of VSM is to highlight sources of waste and eliminate them by implementing a future state value stream. Based on your answers, mark your future state ideas and then you can draw a future-state map with the same set of symbols used for current state mapping.

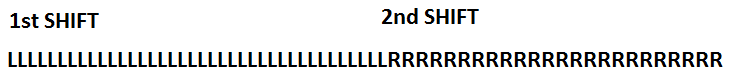

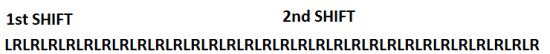

Instead, we need to level the mix of parts evenly over the shift at the pacemaker process. This will force you to reduce the changeover time and with leveling, which requires much more frequent changeovers, the cell’s / line’s production mix looks like this:

We must be sure to kick off these improvements projects by creating a “pull” of the improvement. That is instead of “pushing” a team.

Conclusion:

With the shortened production lead time through the shop floor, the pacemaker process operating consistently to takt time, and fast response to problems, we can comfortably reduce the number of finished goods we hold.

To learn more interesting facts about future state value stream mapping, click on the button below.

Contact us for a consultation on how Hash LLP can help your business with Lean Manufacturing.

+91 9176613965

Join 3500+ Professionals who receive our Weekly Newsletter containing Simple and Practical ideas to help achieve Results in their companies.

Hash Management Services LLP, 2023 © All Rights Reserved