5 important steps to calculate number of operators required for a cell

As a manager, we are inclined to ideas like the cell or line. Consider if a cell is going to be introduced to the existing product line. You will surely estimate, how many operators will be needed for the cell. Below are the steps to be followed to calculate the number operator needed for the cell

Step 1: Record the cycle time of all the operations

Step 2: Tabulate the time taken for the activities done by operators separately. Time taken for carrying out elemental activities should be tabulated for all the operators (excluding machine cycle time) Eg: moving material, loading the component to chuck & turning on the machine, etc.,

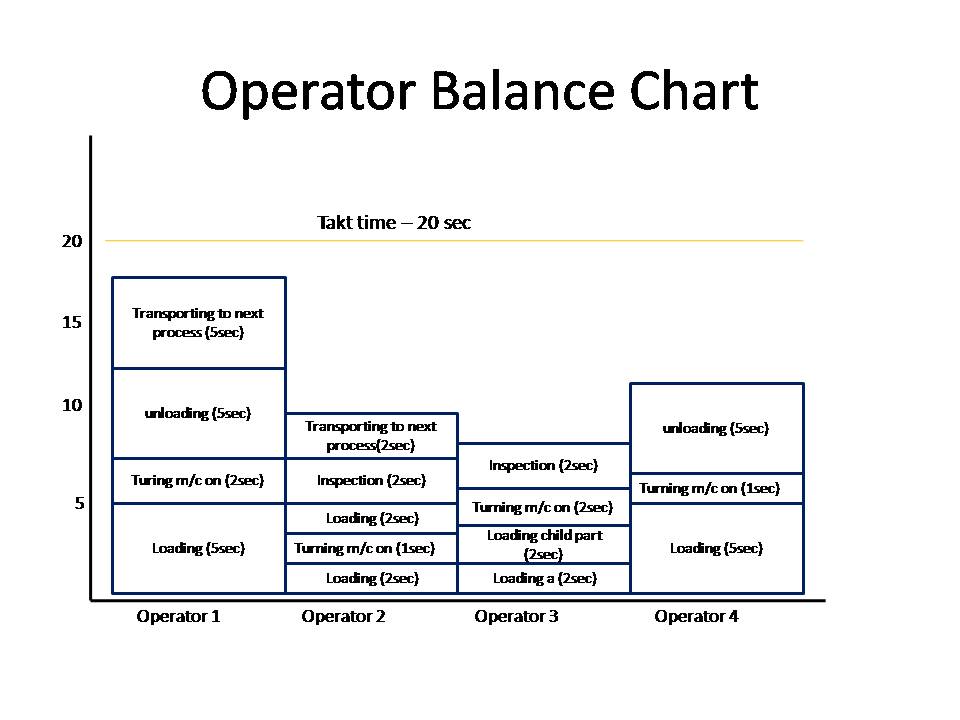

Step 3: create an operator balance chart (OBC) or stack chart- It is a graphical representation, summarizes human work. The height of each box in the stack represents the time for that element. Further, takt time is plotted on the same graph. This helps us to identify, which of the operator`s time is more than takt time (set to be a bottleneck)

Step 4: Nos of operators is estimated by the formula

= Total work content /takt time

From our eg total work content = Operator 1 man time + Operator 2 man time + Operator 3 man

time + Operator 4 man time

(17+9+8+11) sec

= 45 sec

Takt time = 20 sec

Nos of operator = 45/20 = 2.25 operators

Step 5: if the number of operators is in a fraction, guidelines to be followed to find the actual operator needed is explained below

In our eg, we have a fraction of 0.25, by the below table, there is no additional manpower required. The Cell can be managed by 2 operators instead of 3 operators

| Fraction of operators | Guidelines/target |

| < 0.3 | Do not add an extra operator. Further reduce waste and Incidental work (avoidable non value adding activities) |

| 0.3 – 0.5 | Do not add an extra operator yet. After 2 weeks of cell operation and kaizen improvements, evaluate whether enough waste and Incidental work can be taken out |

| >0.5 | Add an extra operator if necessary and keep reducing waste & Incidental work to eventually eliminate the need for that operator in the cell |

This table assumes that operator loading will be in the 90 to 95% range. That is 90 to 95% of each takt interval will be filled with work and operators will not need to watch machines or wait for parts. This table also assumes cell will be introduced and the above-calculated manpower will be used in the cell

Note: Incidental works or avoidable NVA – loading, unloading, quality check and material movement, etc

The above 5 steps summarize the method to calculate the number of operators in the cell.

Contact us for a consultation on how Hash LLP can help your business with Lean Manufacturing.

+91 9176613965

Join 3500+ Professionals who receive our Weekly Newsletter containing Simple and Practical ideas to help achieve Results in their companies.

Hash Management Services LLP, 2023 © All Rights Reserved